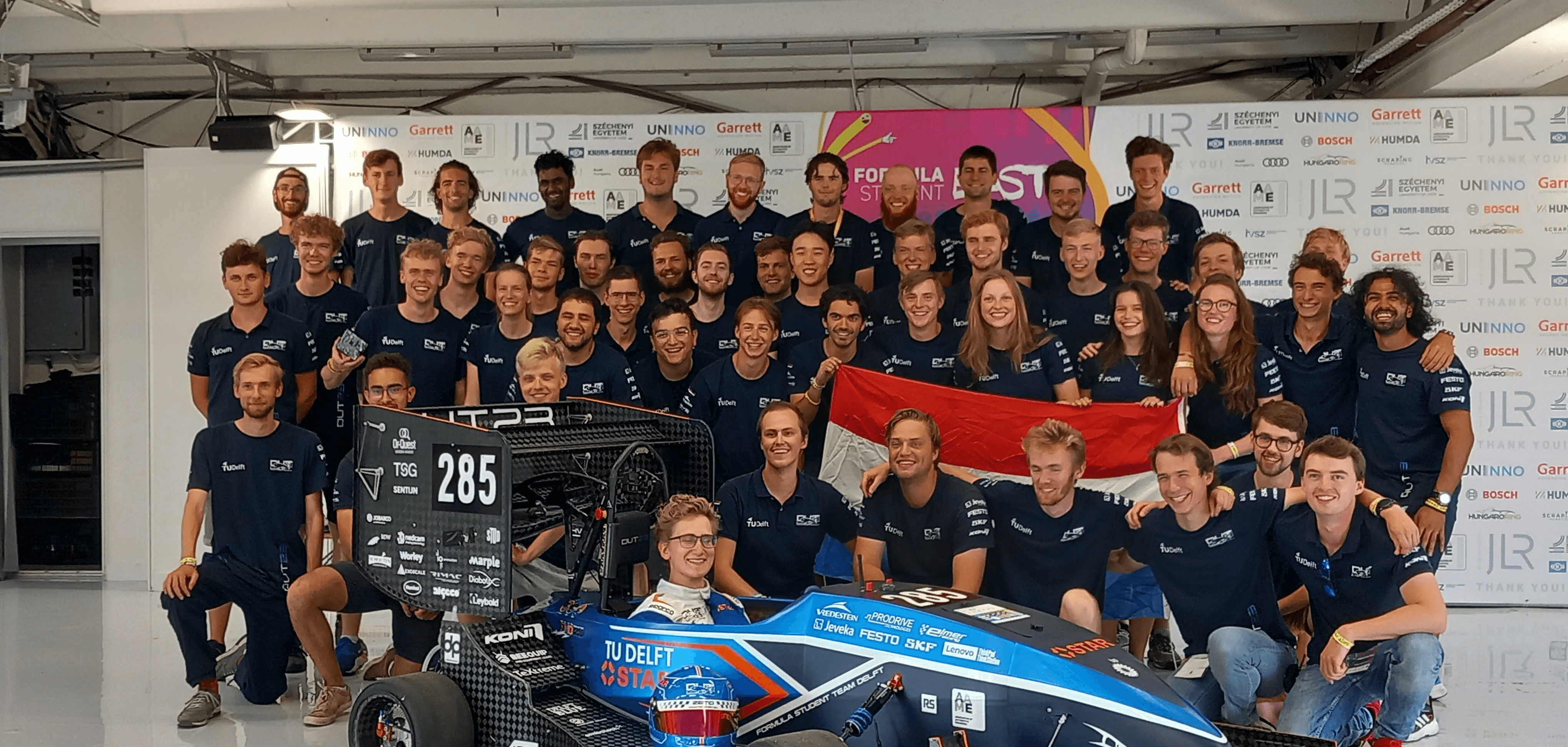

The members of the DUT23

Management team

The Management Team is responsible for the overall project. They ensure that the team has all of the resources they need. Next to that, they make inter-department decisions to make sure that we reach our team goal. They hold oversight over the resources, the time available, the technical quality and the people.

Joris Lans

CEO (Chief Executive Officer)

Emma van den Brink

CFO (Chief Financial Officer)

Stijn Linthorst

COO (Chief Operations Officer)

Baptiste van Hille

CTO (Chief Technical Officer)

Technical chiefs & departments

Aero dynamics

Chief:

Jasper Vallinga

Chassis

Chief:

Moritz Rokitta

Suspension & Drivetrain

Chief:

Nathan Hogendoorn

electronics & embedded

Chief:

Sjoerd Groot

Vehicle Dynamics & controls

Chief:

Jonatan Valk

Powertrain

Chief:

Joup van Donk

Autonomous

Chief:

Job Reijns

Operations

Manager:

Stijn Linthorst

To overview

AERODYNAMICS

The aerodynamics department is in charge of the airflow around the car. They use computational fluid dynamics and test data to optimize the shape of the chassis and design wings and diffusers which maximize downforce and funnel air for cooling. Due to the strict regulations the formula student competition places on aerodynamics, our aero engineers have to be exceptionally creative.

Jasper Vallinga

Chief

Bjorn Wiers

Edoardo Gamba

Fleur Vermeulen

Harmen Schaafsma

Haanbee Park

Lars van der Zwan

Leon Dybioch

Michael Parry

Mrugank Dongre

Pablo Ibón Pérez

Patrick van de Boogaard

Petr Martinek

Reiny Brown

Xinshuo Zhang

Chassis

The chassis department is one of the most versatile in all of Formula Student team Delft, using the expertise of many studies, from mechanical engineering to industrial design. The chassis is designed in detail, incorporating factors such as weight, stiffness and ergonomics. In this process making trade offs is key, for example you can make the car as stiff as you want, but by doing so you're adding weight, so finding the perfect balance between advantages from stiffness and disadvantages from weight is essential to the performance of the car.

Moritz Rokitta

Chief

Ashwin Ruben Ayyanadarkarthik

Daniel Taraczky

Elias Stammeijer

Georgiy Pisarev

Jordi Salvador Masip

Lennart Krieg

Lloyd Koopman

Philippe Beaumont

Milou Butter

Suspension

Connecting the wheels of the car to the chassis may seems like an easy task, but it is one of the most crucial parts in optimizing the performance of the car. To achieve this a blend of skills including FEM simulation, materials testing and systems engineering is required throughout the year. With setup parameters such as spring- and anti roll bar stiffness, camber and toe our suspension engineers ensure that the chassis, wings and tires are always in optimal position, whilst keeping the ride comfortable and interactive for our drivers.

Nathan Hogendoorn

Chief

Arno de Zwart

Daan Hulleman

Jaimy Vlassenbroeck

Ysbrand van Barneveld

Vincent Kramer-Coenen

Drivetrain

Where a conventional car has a engine to gearbox and driveshaft to get the power from the engine to the wheels, in our racers the system is a little different. Our drivetrain department has continued to innovate over the past years, finding new ways to deliver our power, which now happens through a set of planet gears in a bespoke inner wheel concept. This out-of-the-box mentality is a standout feature for our drivetrain department and its engineers, with a constant strive to increase efficiency and decrease weight.

Nathan Hogendoorn

Chief

Boris Keller

Dennis Müller

Leon Thomas

Thomas Stekelenburg

Electronics

Our car is basically a computer on wheels - a very fast one, mind you - so having a good team of electronics experts is crucial to getting around the track as quickly as possible. Mainly populated by electrical engineers, the electronics department offers great insight in high- and low voltage applied electrical systems. There is also a huge responsibility for the embedded department, as the components should be sealed off very well. Not just to comply to the rules of the competitions, but more importantly to ensure the safety of our entire crew. This is especially hard with the accessibility of the electronics systems in mind, as we need to be able to change malfunctioning components in the blink of an eye at the events.

Sjoerd Groot

Chief

Celina Norrman

Erman Ergül

Kasper Vankan

Laura Daumerie

Leon Stadhouder

Lucas Klootwijk

Rik de Moor

Rik Imbens

Embedded

Embedded software writes all of the code which runs on every one of the circuits in the car (there are many circuit boards). While it is easy to spot a broken suspension rod, software problems are more difficult to detect and can be more devastating than issues in most other departments. Fortunately our software team is made up of particularly diligent individuals who ensure our car runs reliably come race time.

Sjoerd Groot

Chief

Akshat Dubey

Pieter Grabijn

Wout van Loevezijn

Vehicle dynamics & controls

In order for the team to successfully design a new car from scratch every year we need to set goals for each department. These goals are based on a combination of previous results and well thought out simulations. This part is handled by our vehicle dynamics department, therefore they shape the car in the early stages of its development.

Jonatan Valk

Chief

David Meszaros

Francesco Coatto

Hovsep Touloujian

Lisa Blom

Maciek Szczesniak

Pierluigi Rinaldi Meneses

Salman Mughal Mohammad

Powertrain

Connected directly to the motors of the drivetrain, is the powertrain. The powertrain transforms the car from just a rolling chassis to a full blown formula student race car. The powertrain department is responsible for the motor controllers and accumulator. The accumulator stores the energy the car needs to complete the 22 km’s of endurance at the competition, and is one of the most complex, and strictly governed (by the rules) assemblies of the car. The motor controllers transform the dc current from the accumulator to the ac current required by the motors. They also contain a large variety of control systems to maximize the car's performance. These motorcontrollers are being designed and tested in house by the powertrain department.

Joup van Donk

Chief

Arturo Arends Martinez

Bartosz Jemioł

Daniel Mudde

Jasper Matthe

Jules Kegeleers

Niels Flikweert

Robert Verheul

Thomas Brehm

Tim Anema

Tim Kok

Autonomous

The frontier of the automotive industry today exists in autonomous technology. In 2019 we built our first autonomous vehicle in partnership with MIT. This year Formula Student has challenged us to build a car which works both with a driver and in a driverless mode. Our autonomous department is tackling this endeavor.

Job Reijns

Chief

Antra Johary

Emma van Zutphen

Koushik Kumaran

Muneeb Syed

Pratham Johari

Robert Kurvits

Robin Appel

Robin Vonk

Sergio Marin Petersen

Operations

The operations department is the hidden motor behind the team. It consists of a variety of students and their main goal is to get the team through the year as smoothly as possible. From arranging team weekends and supplying the team with food to giving business presentations, planning the race events, and contacting sponsors, the tasks of the operations crew are essential for a well-functioning team. You get to meet lots of people and gather broad knowledge of the car and its engineers as you fill in a communicative and managerial role within the team.

sTIJN LINTHORTS

Manager

Florentine de la Court

Isa Meijer

Team manager

Semih Çetin

teammanager@fsteamdelft.nl

+31 6 458 778 77